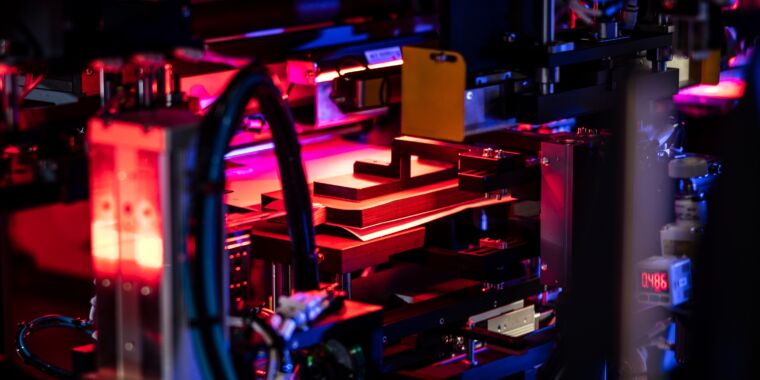

Solid Power, a Colorado-based battery developer, moved one step closer to producing solid-state batteries for electric vehicles on Monday. The company has completed an automated “EV cell pilot line” with the capacity to make around 15,000 cells per year, which will be used first by Solid Power and then by its OEM partners for testing.

“The installation of this EV cell pilot line will allow us to produce EV-scale cells suitable for initiating the formal automotive qualification process. Over the coming quarters, we will work to bring the EV cell pilot line up to its full operational capability and look forward to delivering EV-scale all-solid-state cells to our partners later this year,” said Solid Power CEO Doug Campbell.

Solid-state batteries differ from the lithium-ion batteries currently used in EVs in that they replace the liquid electrolyte with a solid layer between the anode and cathode. It’s an attractive technology for multiple reasons: Solid-state cells should have a higher energy density, they should be able to charge more quickly, and they should be safer, as they’re nonflammable (which should further reduce the pack density and weight, as it will need less-robust protection).

It’s one of those technologies that to a very casual observer is perennially five years away, but over in Europe there are already operational Mercedes-Benz eCitaro buses with solid-state packs.

The tech is taking a little longer to get ready for passenger EVs, but it does appear to be maturing. Solid Power is one of the leading solid-state battery developers, having been established in 2012. Its approach is to use a sulfur-based solid electrolyte and an anode that’s very high in silicon—more than 50 percent, according to Solid Power.

Ars alum Tim de Chant described the production process in a 2021 article for The Wire China:

Apart from the Rocky Mountain backdrop in the distance, Solid Power’s low-slung factory looks similar to any other battery factory. Inside, vats of chemicals are mixed into a slurry and coated onto thin sheets of metal. The chemicals are pressed to the surface by a series of rollers that resemble a miniature printing press, and toward the end of the line, the prepared sheets are cut into pieces, stacked, and pressed into a pouch-type casing.

At this point, other manufacturers would inject the pouch with a fluid known as an electrolyte, which helps ions move across the battery during use. But Solid Power’s innovation allows it to simply seal up the casing and move on to the next one.

This new line is designed to produce the same sized large-format pouch cells currently used by automotive OEMs in their EVs, with cell capacities ranging from 60–100 Ah. BMW and Ford will be the first carmakers to receive cells for testing by the end of this year.